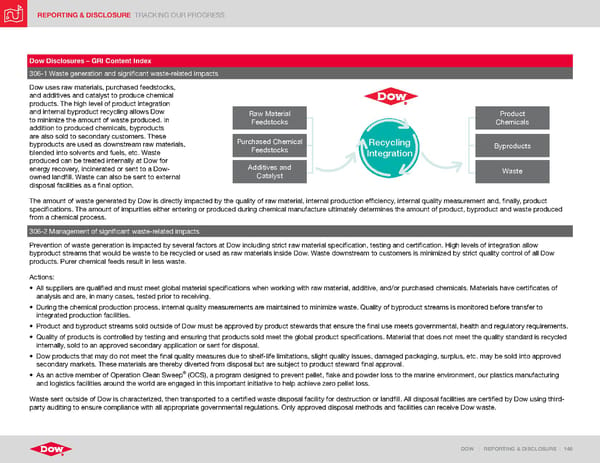

REPORTING & DISCLOSURE TRACKING OUR PROGRESS DOW | REPORTING & DISCLOSURE | 146 Dow Disclosures – GRI Content Index 306-1 Waste generation and significant waste-related impacts Dow uses raw materials, purchased feedstocks, and additives and catalyst to produce chemical products. The high level of product integration and internal byproduct recycling allows Dow to minimize the amount of waste produced. In addition to produced chemicals, byproducts are also sold to secondary customers. These byproducts are used as downstream raw materials, blended into solvents and fuels, etc. Waste produced can be treated internally at Dow for energy recovery, incinerated or sent to a Dow- owned landfill. Waste can also be sent to external disposal facilities as a final option. Recycling Integration Raw Material Feedstocks Purchased Chemical Feedstocks Additives and Catalyst Product Chemicals Byproducts Waste The amount of waste generated by Dow is directly impacted by the quality of raw material, internal production efficiency, internal quality measurement and, finally, product specifications. The amount of impurities either entering or produced during chemical manufacture ultimately determines the amount of product, byproduct and waste produced from a chemical process. 306-2 Management of significant waste-related impacts Prevention of waste generation is impacted by several factors at Dow including strict raw material specification, testing and certification. High levels of integration allow byproduct streams that would be waste to be recycled or used as raw materials inside Dow. Waste downstream to customers is minimized by strict quality control of all Dow products. Purer chemical feeds result in less waste. Actions: • All suppliers are qualified and must meet global material specifications when working with raw material, additive, and/or purchased chemicals. Materials have certificates of analysis and are, in many cases, tested prior to receiving. • During the chemical production process, internal quality measurements are maintained to minimize waste. Quality of byproduct streams is monitored before transfer to integrated production facilities. • Product and byproduct streams sold outside of Dow must be approved by product stewards that ensure the final use meets governmental, health and regulatory requirements. • Quality of products is controlled by testing and ensuring that products sold meet the global product specifications. Material that does not meet the quality standard is recycled internally, sold to an approved secondary application or sent for disposal. • Dow products that may do not meet the final quality measures due to shelf-life limitations, slight quality issues, damaged packaging, surplus, etc. may be sold into approved secondary markets. These materials are thereby diverted from disposal but are subject to product steward final approval. • As an active member of Operation Clean Sweep ® (OCS), a program designed to prevent pellet, flake and powder loss to the marine environment, our plastics manufacturing and logistics facilities around the world are engaged in this important initiative to help achieve zero pellet loss. Waste sent outside of Dow is characterized, then transported to a certified waste disposal facility for destruction or landfill. All disposal facilities are certified by Dow using third- party auditing to ensure compliance with all appropriate governmental regulations. Only approved disposal methods and facilities can receive Dow waste.

ESG Report | Dow Page 145 Page 147

ESG Report | Dow Page 145 Page 147